Guangdong Xindaya 3D Technology Co., Ltd. was established in 2014 with a registered capital of 30 million yuan. It is a metal 3D company that is controlled by Foshan Nanhai Zhongnan Machinery Co., Ltd. and the laser 3D printing R&D team of South China University of Technology. A high-tech enterprise engaged in R&D, manufacturing and application of printing equipment.

The company has passed the ISO9001 quality management system certification of German TUV company, and has a high-quality team with many years of 3D printing equipment research and development, manufacturing services, marketing and business management experience.

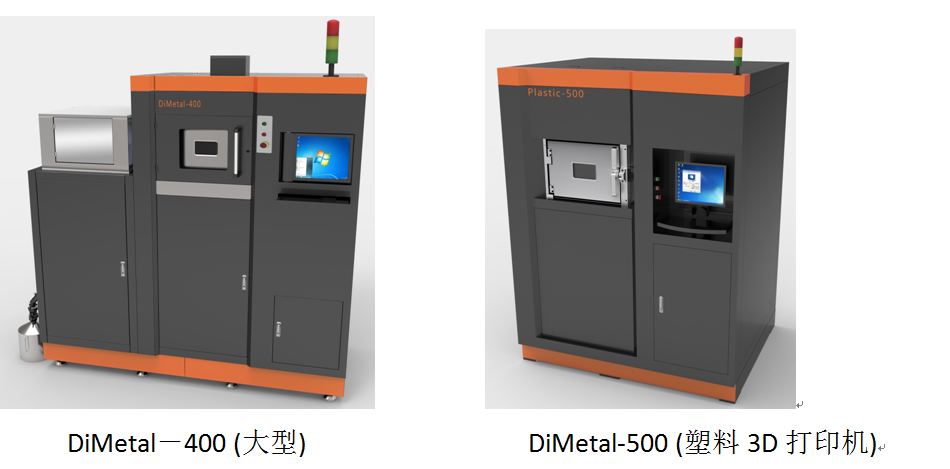

At present, the company has successfully developed the DiMetal series of SLM metal 3D printers, including DiMetal-50 (the first domestic high-precision metal 3D printing desktop), DiMetal-100, DiMetal-280 and Dimetal-400 (industrial-grade 3D printers), etc. The technical level is leading domestically.

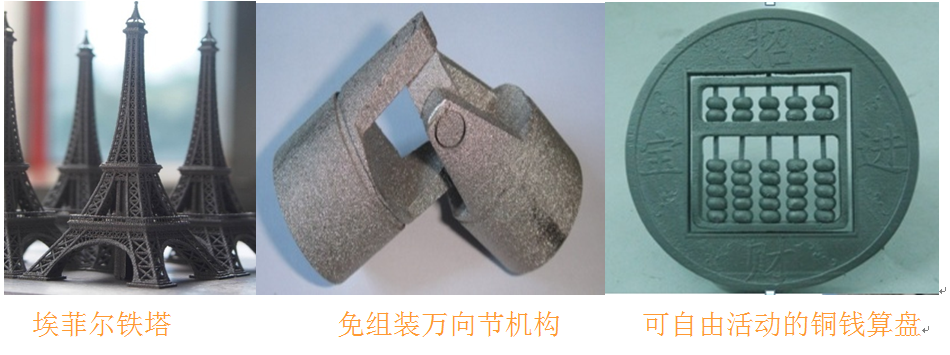

The company has applied for 104 patents, including 15 invention patents, 44 utility model patents, 1 software copyright, and 2 appearance patents. DiMetal series metal 3D printers can form various metal powders such as stainless steel, titanium alloy, aluminum alloy, high temperature nickel alloy, cobalt-chromium alloy, etc., and can form metal parts with any complex structure at one time. The forming performance exceeds that of traditional castings. Through post-processing It can reach or approach the mechanical properties of forged parts.

The company's products can meet the high-precision, high-quality, high-efficiency, and high-flexibility manufacturing requirements of complex precision metal components. It has a wide range of application prospects in the fields of life medicine, medical equipment, precision machinery manufacturing, industrial molds, aerospace industry, key automotive parts, jewelry and handicrafts.

Product-metal 3D printing equipment; to undertake customized metal 3D printing products;

Application areas: life medicine, aviation industry, marine power, ordnance equipment, molds, precision mechanical parts, rapid manufacturing of industrialized mechanical parts samples, and customized crafts.

Break through the constraints of traditional geometric structures and realize the manufacture of any complex parts;

Integrated molding, no need for assembly and welding;

Rapid manufacturing, greatly shortening the R&D innovation cycle;

Save costs and significantly reduce costs;

The product structure is optimized, so that the weight of the product is lighter and the mechanical performance is better;

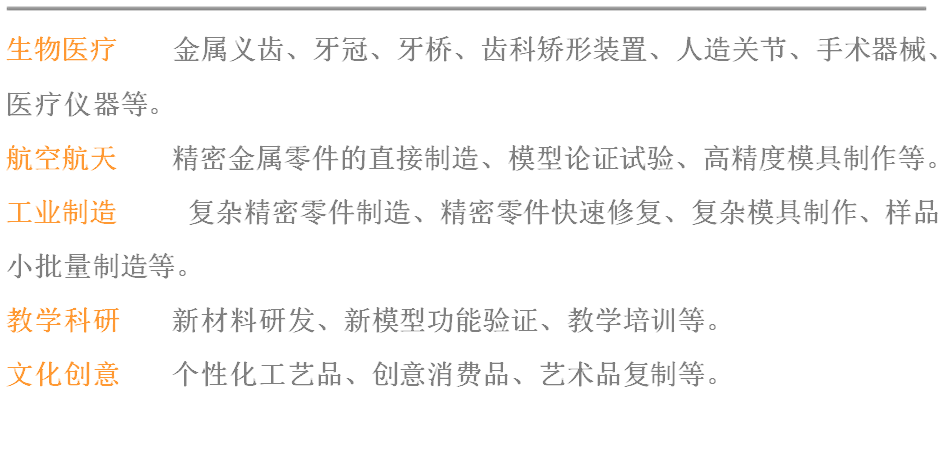

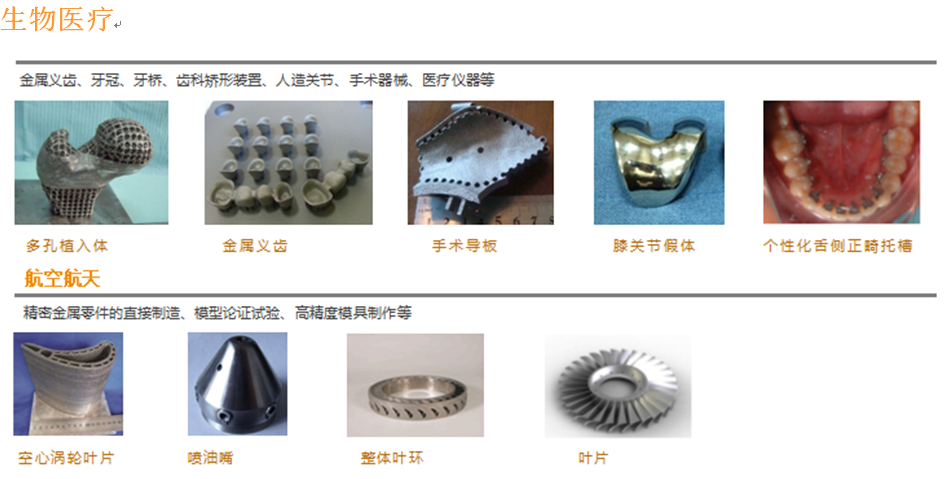

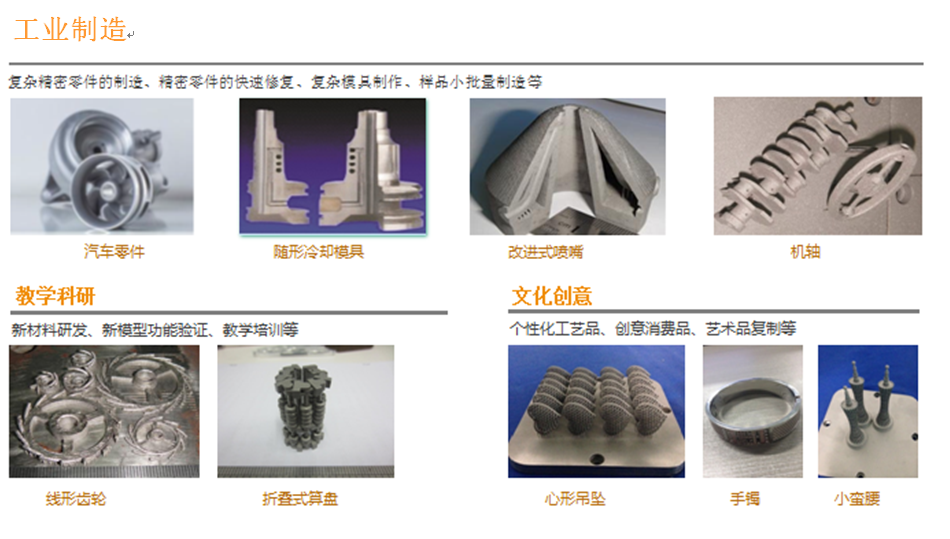

SLM selective laser melting technology has unmatched technical advantages in traditional manufacturing. It can realize the manufacture of metal parts of any structure. It is especially suitable for rapid prototyping of complex and personalized structures, and it can ensure good mechanical properties And effectively reduce manufacturing costs. Therefore, SLM technology is widely used in various fields such as biomedicine, aerospace, industrial manufacturing, teaching and research, and cultural creativity.